RTU vs PLC: Key Differences, Use Cases, and How to Choose the Right System

Automation systems keep operations running smoothly and safely, from controlling a robotic arm on a production line to monitoring an oil pipeline in the desert. At the heart of these systems are two critical devices: Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs).

Though they often work together within SCADA (Supervisory Control and Data Acquisition) systems, the RTU vs PLC debate continues to spark discussion among engineers and systems integrators. Choosing the wrong one can result in unnecessary costs, poor performance, or even system failure.

This article breaks down RTU vs PLC, explaining the difference between RTU and PLC. We will analyse how they operate within SCADA environments and provide a practical guide to help you make the right choice for your application.

If you’re ready to take the next step in your tech career journey, cybersecurity is the simplest and high-paying field to start from. Apart from earning 6-figures from the comfort of your home, you don’t need to have a degree or IT background. Schedule a one-on-one consultation session with our expert cybersecurity coach, Tolulope Michael TODAY! Join over 1000 students in sharing your success stories.

RTU vs PLC: Comparison Table

| Feature | RTU (Remote Terminal Unit) | PLC (Programmable Logic Controller) |

| Primary Function | Remote monitoring & basic control over wide areas | Real-time, high-speed control of machines & processes |

| Environment Suitability | Harsh, remote, outdoor locations | Controlled, indoor industrial environments |

| Power Source | Battery, solar, or low-voltage power | Requires constant, stable power supply |

| Communication | Wireless, satellite, cellular, serial | Wired (Ethernet, fieldbus) |

| Programming Flexibility | Limited; vendor-specific or configuration-based | High; supports Ladder Logic, Structured Text, etc. |

| Autonomous Operation | Yes, can operate independently of central system | No, relies on continuous communication with field devices |

| I/O Capacity | Large-scale I/O; ideal for dispersed sensor networks | Modular I/O; tailored to specific machine/process requirements |

| Response Time | Event-driven; not real-time | Millisecond-level, real-time processing |

| SCADA Role | Field data acquisition and remote control | Local logic execution and machine control |

| Installation Cost | Higher upfront cost, but fewer replacements over time | Lower cost per unit, especially for short-range systems |

| Typical Lifespan | 10–20 years in the field | 8–15 years, depending on usage and environment |

| Other Names | Remote Telemetry Unit, Field Controller | Automation Controller |

RELATED ARTICLE: How Does Virtualization Help with Disaster Recovery?

What is a Remote Terminal Unit (RTU)?

A Remote Terminal Unit (RTU) is a rugged, autonomous device used to monitor and control equipment in remote or challenging environments. It plays a vital role in SCADA systems by gathering real-time data from field devices, such as sensors, valves, and meters, and sending that data back to a central control system for analysis and decision-making.

RTUs are specifically engineered for outdoor and remote deployments where conditions may be too harsh or dangerous for regular equipment. They’re often found in industries like oil and gas, power distribution, water treatment, and telecommunications, places where automation must continue uninterrupted, regardless of climate or connectivity challenges.

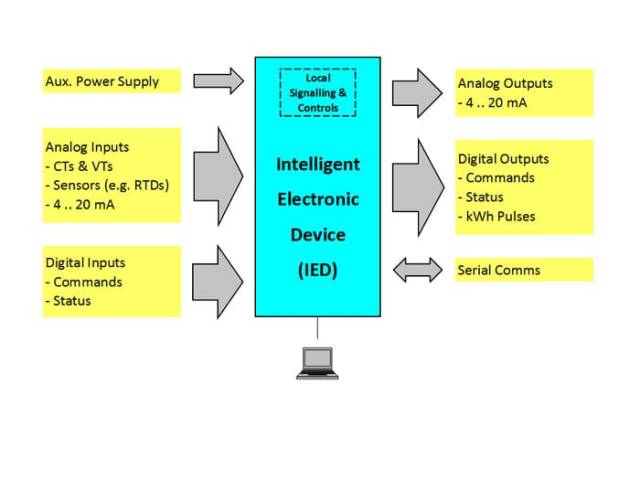

Unlike basic hardware modules, an RTU is a self-contained computer with its own processor, memory, and I/O capabilities. It supports multiple types of inputs and outputs, from analog signals like 4-20mA to digital contact closures, making it highly adaptable across diverse industrial scenarios.

In terms of software, RTU programming language is usually vendor-specific and designed for quick configuration rather than deep custom logic. While it lacks the programming flexibility of a PLC, this simplicity is often an advantage in remote deployments where reliability trumps complexity.

Within a SCADA system, the RTU acts as the field agent in SCADA, gathering data, executing predefined commands, and relaying alerts and diagnostics back to the SCADA hub. Because of its low power requirements and wireless communication support (cellular, satellite, or radio), an RTU can operate independently for years on battery or solar power.

Simply put, the RTU is built for endurance, autonomy, and connectivity in places where traditional control systems can’t survive.

What is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is a digital industrial computer designed to automate mechanical processes, everything from assembly lines and conveyor systems to robotic operations and packaging units. Unlike RTUs, which are optimized for remote locations, PLCs are typically deployed in controlled environments like manufacturing plants, clean rooms, and production floors.

At its core, a PLC continuously monitors input signals (from buttons, sensors, or switches), processes those inputs through a user-defined program, and sends out commands to control machinery like motors, actuators, and valves. The logic is programmed using languages defined by the IEC 61131-3 standard, including Ladder Logic, Structured Text, and Function Block Diagram. This makes PLCs highly flexible and ideal for complex, time-sensitive operations.

Whereas an RTU often focuses on wide-area monitoring and event-driven data collection, a PLC is built for fast, precise control in real-time. It responds to changes in milliseconds, making it the preferred choice for applications where timing and precision are critical, like in car manufacturing or bottling lines.

PLCs also feature a modular and scalable architecture. Engineers can expand I/O modules or swap them out easily to meet changing needs. Modern PLCs may also include built-in HMIs (Human Machine Interfaces) or connect directly to SCADA systems for centralized control and diagnostics.

In short, PLCs are the brains behind most factory automation systems, compact, powerful, and programmable to meet any industrial logic requirement.

READ MORE: Cyber Risk Quantification: Everything You Need to Know

RTU vs PLC: The Core Differences

While both RTUs and PLCs are pillars of industrial automation, their capabilities and use cases are far from interchangeable. Understanding the difference between RTU and PLC is critical for selecting the right system, especially when designing or upgrading a SCADA network.

Below is a breakdown of their key distinctions:

1. Deployment Environment

- PLCs operate in controlled indoor settings, such as manufacturing plants, where temperature, humidity, and power supply are stable.

- RTUs are designed for rugged, remote environments, pipelines in the desert, water stations in rural areas, or substations in icy climates. They’re built to withstand vibrations, extreme heat or cold, and poor connectivity.

2. Communication and Connectivity

- PLCs typically rely on wired connections, ensuring ultra-fast response times but limiting deployment flexibility.

- RTUs, on the other hand, are communication powerhouses. They support wireless, cellular, radio, and even satellite communication, making them ideal for SCADA systems that span wide geographic areas.

3. Power and Independence

- PLCs need a constant, stable power supply and are generally backed by facility-level power infrastructure.

- RTUs are low-power devices and can operate independently using solar panels or batteries, allowing for sustained use in unmanned or power-scarce locations.

4. Input/Output Capabilities

- RTUs are equipped with larger and more varied I/O options, ideal for monitoring multiple sensor types over wide areas.

- PLCs offer modular, high-speed I/O control designed for quick actuation in machine operations. The modularity allows engineers to scale up or down depending on the machine’s logic demands.

5. Programming and Logic Control

- PLCs support versatile and standardized programming languages like Ladder Logic and Structured Text, allowing for sophisticated control schemes.

- RTU programming language is often proprietary or menu-based, focusing more on configuration than deep customization. This makes RTUs easier to deploy in the field but less flexible for advanced logic.

6. Cost Efficiency

- PLCs are more cost-effective for localized, high-speed control in a single facility.

- RTUs may have a higher upfront cost, but are more efficient for remote, multi-point monitoring, reducing the need for multiple devices across vast distances.

SEE ALSO: Difference Between Risk Assessment and Risk Management

RTU vs RIO: Understanding the Distinction

In automation design, the terms RTU and RIO are sometimes mistakenly used interchangeably, but they serve very different purposes. To make smart decisions in system architecture, it’s essential to understand the distinction between a Remote Terminal Unit (RTU) and a Remote I/O (RIO) module.

What is RIO?

A Remote I/O module is essentially an extension of a PLC’s input/output capacity. It doesn’t make independent decisions or run logic by itself. Instead, it sends raw sensor and device signals back to the PLC over a communication link, often using industrial Ethernet or fieldbus protocols like Modbus, Profibus, or EtherNet/IP.

RIOs are passive, dependent on a central controller (like a PLC or DCS) to process data and issue commands. Think of them as “I/O mirrors” located far from the PLC, reducing the need for excessive wiring across a large facility.

RTU vs RIO: The Key Differences

- Independence: An RTU is a standalone controller with its own processing power, logic, and communication modules. It can function autonomously and control equipment even when communication with the central system is interrupted. A RIO, however, cannot function without a PLC; it’s an I/O relay, not a decision-maker.

- Intelligence: RTUs can run logic, initiate alerts, and interact with SCADA or DCS platforms. RIOs do none of this; they only collect or relay data.

- Use Cases: RTUs are used in remote field operations, where decisions need to be made locally without relying on central communication. RIOs are used in large but centralized systems, like expansive production floors, where extending I/O points is more practical than deploying new controllers.

In essence, if your goal is to control or monitor devices from afar and you need that remote node to have logic, communication, and autonomy, you need an RTU. If you just need to extend your PLC’s reach, a RIO will do the job; no need for the intelligence of an RTU.

MORE: Whitelisting vs Blacklisting: What’s the Difference

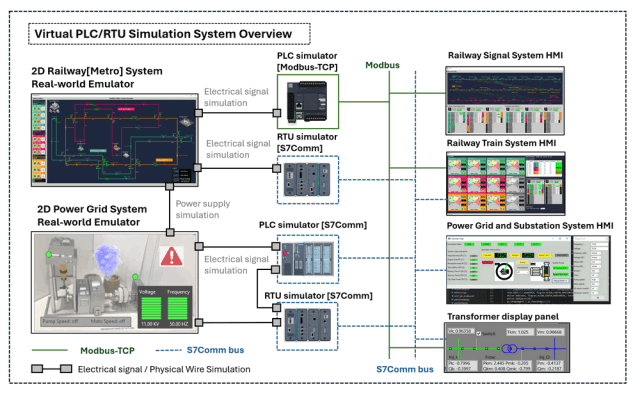

RTU vs PLC in SCADA Systems

The SCADA (Supervisory Control and Data Acquisition) architecture is built on a layered structure, field devices collect data, controllers process it, and the central system supervises the entire operation. Both PLCs and RTUs are integral to this architecture, but they play very different roles within it.

Understanding how RTU vs PLC in SCADA functions can help engineers design more efficient, scalable, and resilient control systems.

RTU in SCADA: The Remote Scout

An RTU in SCADA serves as the system’s long-range scout. Deployed across wide, remote areas, pipelines, substations, water reservoirs, RTUs monitor field conditions and transmit data back to the central SCADA interface. They often operate in isolation, powered by solar or battery systems, and can trigger local alarms or control logic without needing real-time human interaction.

For example, in a power distribution network, an RTU may monitor transformer load levels and send immediate alerts to the control room if an overload is detected, even if internet or radio connectivity is temporarily lost.

PLC in SCADA: The Real-Time Enforcer

PLCs, by contrast, excel in real-time machine control. Within a SCADA environment, PLCs handle complex automation logic and fast process control tasks on the factory floor or within a localized plant. The PLC continuously gathers input data (such as sensor readings), processes it based on programmed logic, and immediately activates outputs (such as motors or valves).

A good example would be a beverage production line where a PLC ensures the exact volume of liquid is dispensed into each bottle, hundreds of times per minute, while simultaneously tracking temperature and pressure conditions.

When They Work Together

In many SCADA systems, RTUs and PLCs are used side-by-side. A SCADA dashboard may pull data from RTUs in the field and control production machinery through PLCs in the plant. The synergy of remote monitoring (via RTUs) and localized precision control (via PLCs) results in a robust, end-to-end automation framework.

Summary: Choosing the Right Fit in SCADA

- Choose RTUs when your SCADA system spans remote, environmentally extreme locations.

- Use PLCs when real-time responsiveness and precision are critical in a centralized or controlled environment.

- In many advanced systems, hybrid architectures incorporating both RTUs and PLCs provide the best of both worlds.

Industry-Specific Use Cases

Different industries have different priorities; some require ultra-fast precision, while others prioritize remote durability and wireless data transmission. Understanding where each controller thrives helps clarify the RTU vs PLC conversation.

1. Oil and Gas Industry – RTU Dominance

In oil and gas, assets are often spread across vast and hazardous terrains—from offshore rigs to desert pipelines. This makes the Remote Terminal Unit the preferred choice. RTUs offer:

- Reliable remote monitoring of pressure, temperature, and flow.

- Wireless communication via satellite or cellular.

- Rugged hardware that withstands extreme heat, cold, and humidity.

- Autonomous control when network connectivity is lost.

Use Case: An RTU installed along a pipeline can detect a sudden pressure drop, signaling a potential leak. It can automatically shut down that section and alert the central SCADA system, no human needed on-site.

2. Manufacturing and Assembly Lines – PLC Leadership

In manufacturing, speed and accuracy are everything. That’s where PLCs shine. Their tight response times and real-time control make them ideal for:

- Robotic arm coordination.

- Conveyor belt timing.

- Quality control inspection systems.

- Complex decision logic in production workflows.

Use Case: In a car manufacturing plant, multiple PLCs control robotic welding arms, ensuring every weld is made in sync with moving car frames, down to the millisecond.

3. Water and Wastewater Treatment – RTU Reliability

Water plants often include multiple remote pumping stations and reservoirs, requiring autonomous and weather-resistant monitoring. RTUs are the better choice because:

- They can be solar-powered and left unattended.

- They send alerts when levels, turbidity, or chemical balances fall outside thresholds.

- They can function in flood-prone or dusty outdoor environments.

Use Case: An RTU at a remote wastewater station monitors pump status and chlorine levels, alerting operators if anything goes off-spec.

4. Building Automation – PLC Versatility

In modern smart buildings, PLCs are often used to manage HVAC systems, lighting, access control, and fire suppression. They enable centralized control with custom programming for:

- Temperature optimization.

- Lighting schedules.

- Emergency response triggers.

Use Case: A PLC in a corporate building can regulate energy usage by automatically adjusting HVAC settings based on room occupancy detected through sensors.

READ: What Is the Difference Between EDR and SIEM?

Choosing Between RTU and PLC

Making the right choice between an RTU and a PLC isn’t about brand or popularity, it’s about purpose. Your decision should be guided by the environment, system requirements, and long-term maintenance needs. Let’s break it down.

1. Application Requirements

Start by defining your control objectives:

- Are you monitoring remote infrastructure (like pipelines or water stations)? → RTU

- Are you controlling fast-moving machinery in a factory? → PLC

- Do you need both remote sensing and local control? → Consider a hybrid RTU + PLC setup.

Also, evaluate the number and type of I/O points required. If you need hundreds of sensors and relay outputs across distances, the RTU’s high I/O capacity is a better fit.

2. Scalability

- PLCs are ideal for scalable systems within a plant. You can expand with modular I/O as your operations grow.

- RTUs are better when you’re scaling across geographic locations, especially when adding new stations or remote assets.

3. Programming and Configuration

- If your team is comfortable with Ladder Logic, Structured Text, or Function Block Diagrams, a PLC offers the programming flexibility needed for advanced control.

- If you need a plug-and-play configuration with limited need for custom logic and faster deployment across the field, an RTU with simpler, often menu-driven interfaces is a better match.

Also, consider how frequently your team will update the logic. Frequent logic changes lean toward PLCs. Stable, long-term deployments lean toward RTUs.

4. Environmental Considerations

- Controlled Indoor Environment? → Go with a PLC.

- Unpredictable Outdoor Conditions? → RTU wins with its rugged design, wider temperature tolerance, and power independence (battery/solar-ready).

5. Communication Requirements

- Need real-time, high-speed control over local machinery? → PLC.

- Need event-based, wireless communication across long distances? → RTU.

RTUs shine where connectivity is limited or intermittent. They can buffer data and transmit only when triggered by specific thresholds or alarms.

6. Budget and Lifecycle Cost

- PLCs often have a lower initial cost, especially for small-scale, local automation.

- RTUs provide long-term cost savings when deployed in the field, as they reduce the need for on-site personnel and allow centralized monitoring of multiple sites.

In short:

Choose a PLC when precision, speed, and complex control logic are priorities in a local environment.

Choose an RTU when you need remote, rugged, autonomous data gathering and basic control over distributed assets.

Conclusion

The RTU vs PLC comparison isn’t a matter of which is better; it’s about what fits the job best. Both devices are cornerstones of industrial automation and SCADA systems, but they’re built with different environments and functions in mind.

If you need rugged, autonomous field monitoring across wide, remote terrains, especially with wireless communication and event-driven data reporting, then a Remote Terminal Unit is your best ally.

If your focus is on real-time, high-speed control within a localized, stable environment, where precision, programmability, and quick feedback loops are critical, then the PLC is your tool of choice.

In many systems, the most efficient design isn’t about choosing one or the other; it’s about strategically combining both. RTUs can monitor and report from afar, while PLCs drive fast logic at the core. Together, they power modern SCADA architectures that are scalable, intelligent, and future-ready.

As the industrial world leans into smart automation, AI, and the cloud, the lines between these devices will continue to blur. But the core principle remains the same: choose based on environment, communication needs, control complexity, and long-term operational goals.

FAQ

What is another name for RTU?

Another common name for an RTU (Remote Terminal Unit) is a Remote Telemetry Unit. Both terms are used interchangeably, especially in utility and SCADA applications. The key idea is that RTUs enable the remote collection and transmission of data from field devices to a central monitoring system. Some vendors or industries may also refer to them as field controllers or remote monitoring devices.

How much does an RTU cost?

The cost of an RTU varies widely depending on its features, I/O capacity, ruggedness, and communication capabilities. On average:

Basic RTUs (limited I/O, minimal features) can range from $800 to $2,500.

Mid-range industrial RTUs with advanced communication and rugged design typically cost between $3,000 and $6,000.

High-end RTUs with extensive I/O, redundancy, built-in switches, and enhanced durability can exceed $10,000.

Custom configurations, vendor support contracts, and cybersecurity features may also affect pricing.

What is the lifespan of an RTU?

A well-maintained RTU has a typical lifespan of 10 to 20 years, depending on environmental conditions, build quality, and usage. RTUs designed for extreme climates or mission-critical operations are built with industrial-grade components, allowing them to operate reliably for long periods without human intervention. Regular firmware updates and preventive maintenance can extend their useful life further.

How does an RTU unit work?

An RTU unit works by acting as an intermediary between physical field equipment and a central control system (usually SCADA). Here’s how:

– It collects real-time data from sensors, meters, or switches (like pressure, temperature, voltage).

– It processes or filters the data locally.

– It communicates that data wirelessly or via cable to a central monitoring hub.

– Based on predefined logic or remote commands, it can also trigger actions (like opening a valve or shutting down a pump).

RTUs are ideal for sites where human presence is limited, enabling remote control, data acquisition, and autonomous fault handling.